Car filters are critical components in modern vehicles, protecting engines, fuel systems, and cabins from harmful contaminants. The effectiveness of these filters directly impacts vehicle performance, longevity, and emissions. To ensure quality and reliability, car filter suppliers employ rigorous testing methods during the design, production, and quality control phases. Understanding these testing methods provides insight into how filters maintain high standards of performance and durability in diverse operating conditions.

Car filter suppliers use a variety of testing methods to evaluate the efficiency, durability, and structural integrity of filters. These tests are designed to simulate real-world conditions and assess how well a filter can remove contaminants while maintaining proper airflow or fluid flow. A reputable Car Filter Supplier employs multiple testing techniques to verify that each filter meets or exceeds original equipment manufacturer (OEM) specifications, ensuring reliability and safety for consumers.

Filtration Efficiency Testing

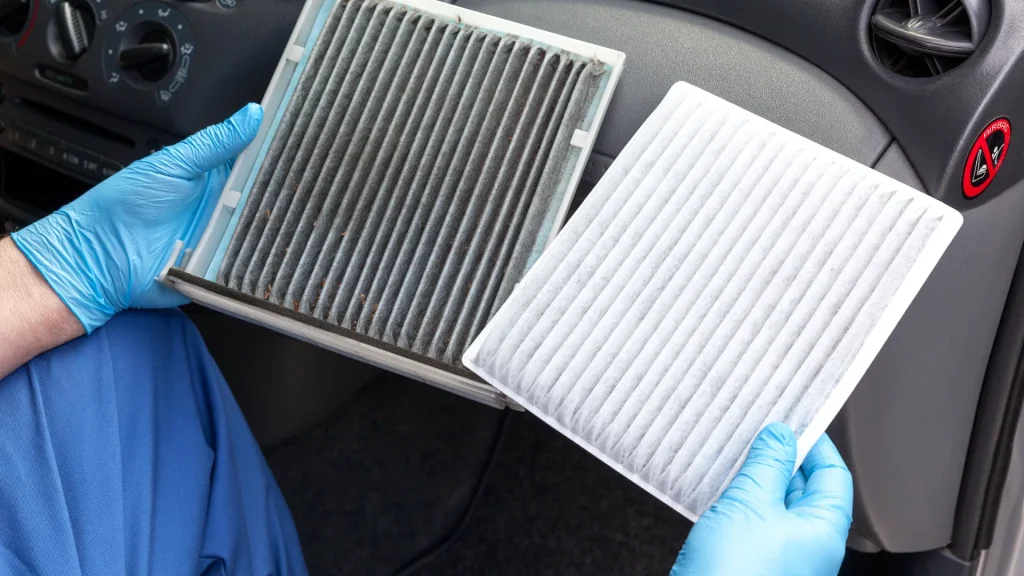

Filtration efficiency testing measures a filter’s ability to capture particles of various sizes. This test is essential for air, oil, fuel, and cabin air filters. High-efficiency filters can trap smaller particles while still allowing adequate flow of air, oil, or fuel. During testing, filters are exposed to a controlled stream of particles, and instruments measure the percentage of particles retained by the filter media.

Air filters, for example, are tested with dust or pollen particles to determine their capacity to prevent debris from entering the engine. Oil and fuel filters undergo similar testing using metal or carbon particles to ensure they prevent contaminants from reaching sensitive components. This testing guarantees that the filter effectively protects critical vehicle systems under typical operating conditions.

Flow and Pressure Drop Testing

Filters must not only capture contaminants but also allow fluid or air to pass through without excessive resistance. Flow and pressure drop testing evaluates how a filter performs under normal and extreme operating conditions. In this test, air or liquid is forced through the filter media, and pressure measurements are taken to determine the resistance created by the filter.

A low pressure drop indicates that the filter allows adequate flow without restricting system performance. Conversely, a high pressure drop may reduce engine efficiency, increase fuel consumption, or strain HVAC systems in vehicles. By conducting flow and pressure drop testing, suppliers ensure that filters strike the right balance between filtration efficiency and system performance.

Burst and Structural Integrity Testing

Filters must maintain their structure under high pressures, temperatures, and fluid flow rates. Burst testing and structural integrity testing evaluate a filter’s ability to withstand extreme conditions without collapsing or leaking. Filters are subjected to pressures higher than those expected in normal operation, and their physical integrity is monitored.

This testing is especially important for oil, fuel, and hydraulic filters, which operate under high-pressure conditions in engines and transmissions. Ensuring that filters maintain their shape and sealing ability prevents contaminants from bypassing the filter and causing damage to critical components.

Contaminant Holding Capacity Testing

Contaminant holding capacity testing determines how much dirt, dust, or particles a filter can retain before it becomes saturated and requires replacement. During this test, filters are exposed to increasing amounts of simulated contaminants, and the point at which the filter’s performance begins to decline is measured. This helps determine recommended service intervals and replacement schedules for different driving conditions.

Filters with higher contaminant holding capacity last longer and provide consistent protection over time. By evaluating holding capacity, car filter suppliers ensure that their products offer reliable performance and reduce maintenance frequency for vehicle owners.

Environmental and Temperature Testing

Filters must perform reliably under varying environmental conditions. Temperature and humidity testing evaluates filter performance in extreme heat, cold, or moisture. Some filters, such as cabin air filters with activated carbon or oil filters with synthetic media, are particularly sensitive to environmental conditions. Testing ensures that filters maintain efficiency, structural integrity, and airflow under real-world temperature and humidity fluctuations.

Environmental testing also helps suppliers meet global standards and regulations, ensuring that filters perform effectively in diverse geographic regions and climates.

Compliance and Certification Testing

Car filter suppliers often perform testing to meet international standards and regulatory requirements. Certifications such as ISO 9001 for quality management and ISO 14001 for environmental management ensure that production processes and testing methods adhere to strict industry guidelines. Compliance testing provides vehicle manufacturers and consumers with confidence that the filters are safe, reliable, and environmentally responsible.

Conclusion

Testing methods used by car filter suppliers are essential for ensuring the efficiency, durability, and reliability of filters in modern vehicles. Filtration efficiency, flow and pressure drop, burst and structural integrity, contaminant holding capacity, environmental performance, and compliance testing all contribute to producing high-quality filters that protect engines, fuel systems, and cabins. Partnering with a trusted Car Filter Supplier guarantees access to rigorously tested filters that meet OEM standards, deliver consistent protection, and enhance overall vehicle performance. By understanding these testing methods, vehicle owners can appreciate the role of high-quality filtration in maintaining reliable, efficient, and safe vehicles.